There has been a resurgence of manufacturing nationwide and our program reflects a program that is extremely flexible and reflects this dynamically-changing field, which encompasses several sub-disciplines. Manufacturing covers a broad range of processes and modeling/simulation/experimentation activities all focused on the conversion of materials into products. Typical processes range from conventional material removal by cutting to semiconductor and nanomaterial processing techniques such as chemical mechanical planarization to additive processes such as 3D printing and spray processing. Modeling and simulation attempts to predict the behavior of these processes to insure efficient and optimal performance. A companion set of activities in sensors and process monitoring, automation, internet based design to manufacturing, cyber-physical infrastructure, quality control, reliability are part of manufacturing. Manufacturing is receiving special attention at the moment in the United States as a driver of innovation and competitiveness and a major contributor to employment.

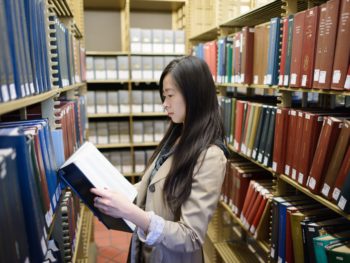

Overall, manufacturing combines classical topics in design, controls and materials processing. The activity in manufacturing today is built on a long history of fundamental research and education by pioneers such as Erich Thomsen and Shiro Kobayashi. Recent activities have moved away the more traditional areas of metal forming and plasticity to design and advanced manufacturing integration, new manufacturing technologies, specially for energy reduction and alternate energy technologies, precision manufacturing, computational manufacturing and sustainable manufacturing. Much of the research includes development of tools for engineering designers to include the impact of manufacturing in the design process as well as, more recently, the life cycle impacts for the product. Education and research in manufacturing is exceptionally well integrated with industry in terms of internships, research support and student placement. The Mechanical Engineering manufacturing group consists of a number of core faculty, whose primary interest and activity is in manufacturing, along with a number of closely affiliated faculty whose work overlaps significantly with manufacturing processes or technologies.

Ongoing collaborations with our colleagues in Electrical Engineering and Computer Science, Materials Science and Engineering and the Haas School of Business (e.g. the Center for Responsible Business for research collaboration on sustainable manufacturing) continue to be a vital part of our program. There is a wide range of courses that a student can take, due to the nature of the discipline. Members of the manufacturing group teach the following courses:

Undergraduate Courses: E 25, E 26, E 27, ME C85/CEE C33, ME 101, ME 104, ME 122, MEC 180, CEE C133

Graduate Courses: ME C201/MSE C286, MEC 202C/MSE C287, ME 220, ME 280A, ME 290D, ME 290 I, ME 290L, ME 290R

We also strongly encourage students to take courses outside of the group, to expose them to the wide range applications that are critical components of a well-rounded education.

Manufacturing continues to be a critical field for research and industrial development over many sectors. All future energy, transport, medical/health, life style, dwelling, defense and food/water supply systems will be based on increasingly precise elements and components produced from increasingly challenging materials and configured in complex shapes with demanding surface characteristic. This includes manufacturing products for an energy and environmentally aware consumer (such as autos, consumer products, buildings, etc.), manufacturing alternate energy supply systems (e.g. fuel cells, solar panels, wind energy systems, hybrid power plants, etc.), machine tools and the “machines that build the products” requiring less energy, materials, space and better integrated for efficient operation and efficient factory systems and operation. This is all required in an environment of increasing regional, national and international government regulations covering all aspects of the manufacturing enterprise. This means that for the foreseeable future, the field is expected to be well supplied with challenges to drive innovation in research and education.

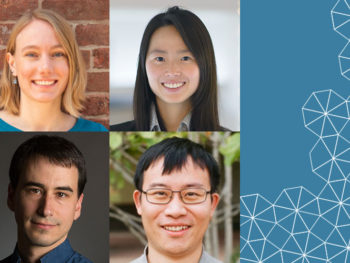

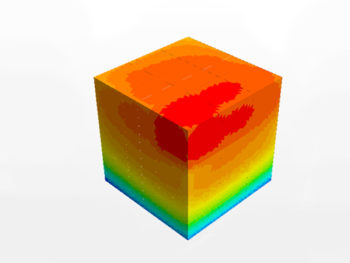

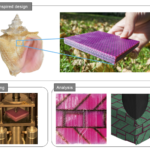

In summary, modern manufacturing can be characterized by three basic processing strategies – additive, subtractive and near-net shape. These are somewhat self explanatory in their names. Near-net shape, aka forming/forging and molding techniques. Subtractive, for example, machining, is the “old standby” process used extensively in basic machine construction but is quite limited as applied to higher technology products. Additive manufacturing, ranging from deposition processes to the more recent rapid prototyping approaches, is an area that offers much future potential for both accurate and fast creation of complex products. Additive manufacturing (AM) and Rapid-Prototyping (RP) have received a great deal of attention for a number of years. In particular, the idea of 3-D Printing (3DP) has received quite a large amount of press. According to ASTM, AM is defined as the “process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies.” In many cases, this process is referred to as additive- fabrication, processes, techniques, layer manufacturing and freeform fabrication. The basic term is used in conjunction with the product life cycle from rapid-prototyping pre-production to full scale production. The core faculty (McMains, Taylor, Wright, Yamazaki and Zohdi) are directly involved in the modeling, simulation and implementation of these techniques, with significant funding from a wide array of agencies and companies.

The Major Field Advisors for each research area are listed here.

Core Faculty:

The following affiliated faculty also conduct research in manufacturing or work that impacts manufacturing: David M. Auslander, Homayoon Kazerooni, Kyriakos Komvopoulos, and Liwei Lin.

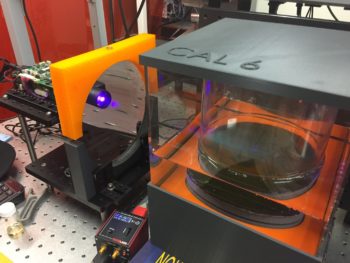

Manufacturing Labs:

Computational Manufacturing and Materials Research Laboratory

Design for Nanomanufacturing

Gu Research Group

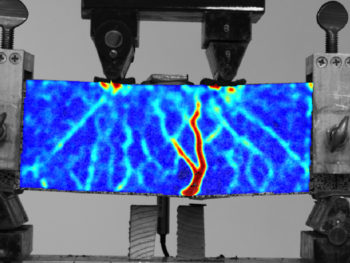

Berkeley Manufacturing Research in the News: